As you folks all might know, there is two mainstream techniques to do 3D printing at home nowadays:

FDM, or fused filament fabrication and

SLA, or stereolithography.

The first technique uses a continuous filament of a thermoplastic material, which is melted in a so called “hot end” onto a build plate. By movement of the heated printer extruder head, your object starts to grow from bottom to top. Fused filament printing is the most poplular process of 3D printing right now.

The second technique uses photochemical processes by which UV light causes chemical monomers and oligomers to cross-link together to form polymers. The material for this process is liquid resin, which is filled into a basin, sitting on top of a UV screen. In stereolitography everything is upside down: The build plate comes down from the top, the UV screen hardens one layer of the resin, which then sticks to your build plate.

In the FDM technique you normally print a layer height around ~0,12 – 0,20 mm, which translates into more or less visible lines. The SLA technique usually prints around ~0,025 – 0,05 mm, which is not visible at all, except in some very specific structures and angles. In return, uncured resin is highly toxic and during polymerization, volatile organic components (VOCs) are released into the air. So you need personal safety equipment, very good ventilation and activated carbon filters.

VOC health effects may include:

- Eye, nose and throat irritation

- Headaches, loss of coordination and nausea

- Damage to liver, kidney and central nervous system

- Some organics can cause cancer in animals, some are suspected or known to cause cancer in humans

So long story short, both techniques have their advantages and disadvantages. 😉

Now there is this awesome 3D miniature designer, Evan Carothers or EC3D Design, who engineers most of his miniatures to be printable without supports. And they are supposed to work with both FDM and SLA techniques.

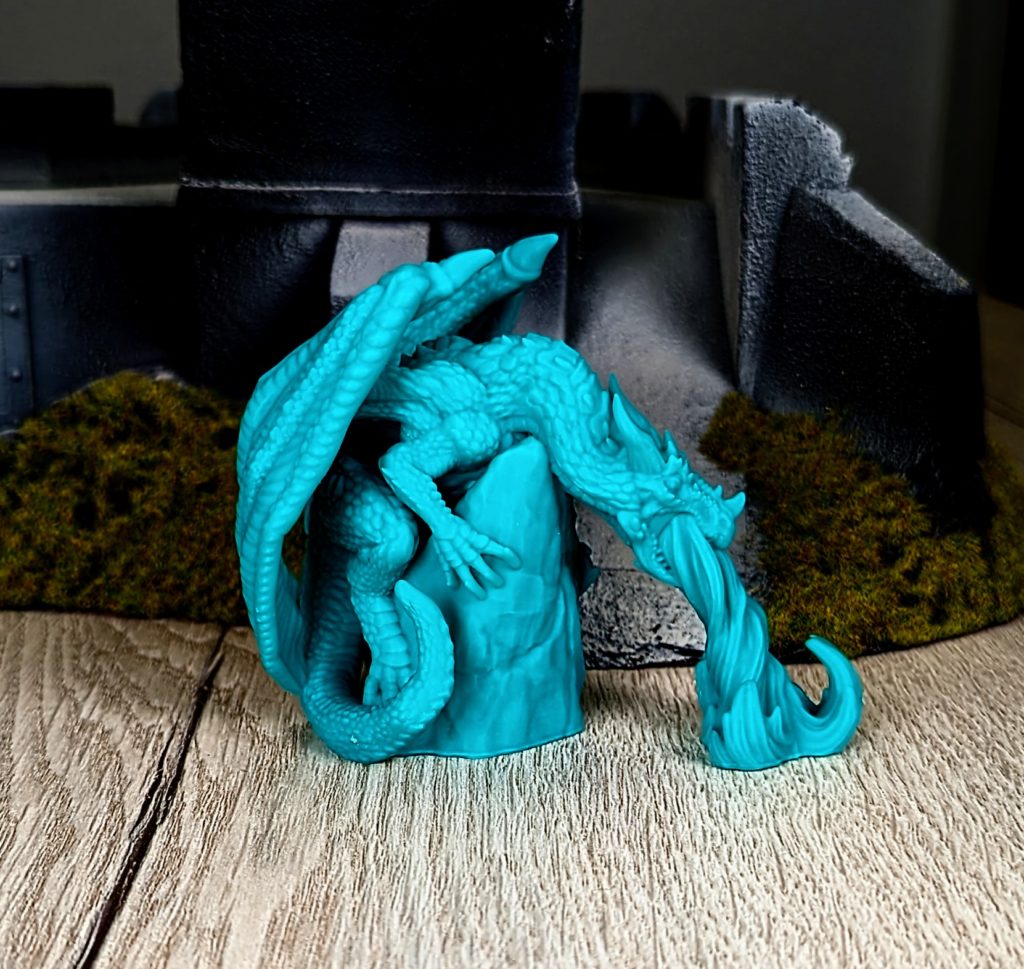

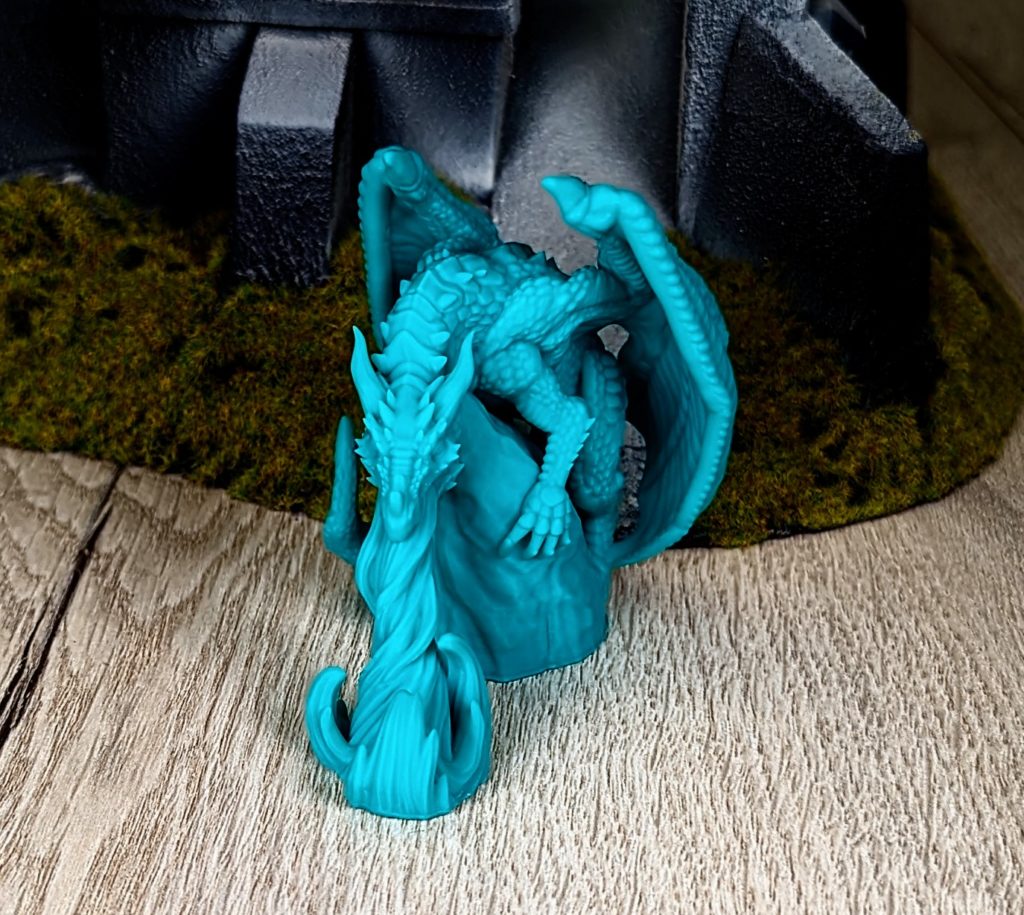

And as a test print, I decided to print his “Young Dragon” miniature in both black PLA and mint ABS-like Resin. These are the results:

And I am happy with both results, honestly. The resin print (mint coloured) was no big surprise, resin always gives smooth surfaces. No need for supports is a very nice amenity though. 😉

The PLA print (black coloured) worked very well, too. Although you can see the expected layer lines. So for sure, resin is better if you want to apply a nice top notch paintjob.

But on the other hand, if you are on a tight budget, PLA prints are something you could consider. With my calculations I can sell one resin Young Dragon for 15,75 Euro. Which includes all the hustle with post-processing of resin (washing in alcohol, UV light curing) and the safety and ventilation measures.

The PLA Young Dragon could be sold for 8,75 Euro, which is almost half of what I have to ask for the resin version of the same model. So in the end it is really up to you. What are your needs when it comes to details and quality of the model and how big or small is your budget.

If you want this dragon, too but lack the capacity to print him yourself, just take a look in the DicePerSecond webshop, you just might find him there. 😉

So lets close this blog entry with a nice painted version of said Young Dragon. 🙂